Trans American Auto Project

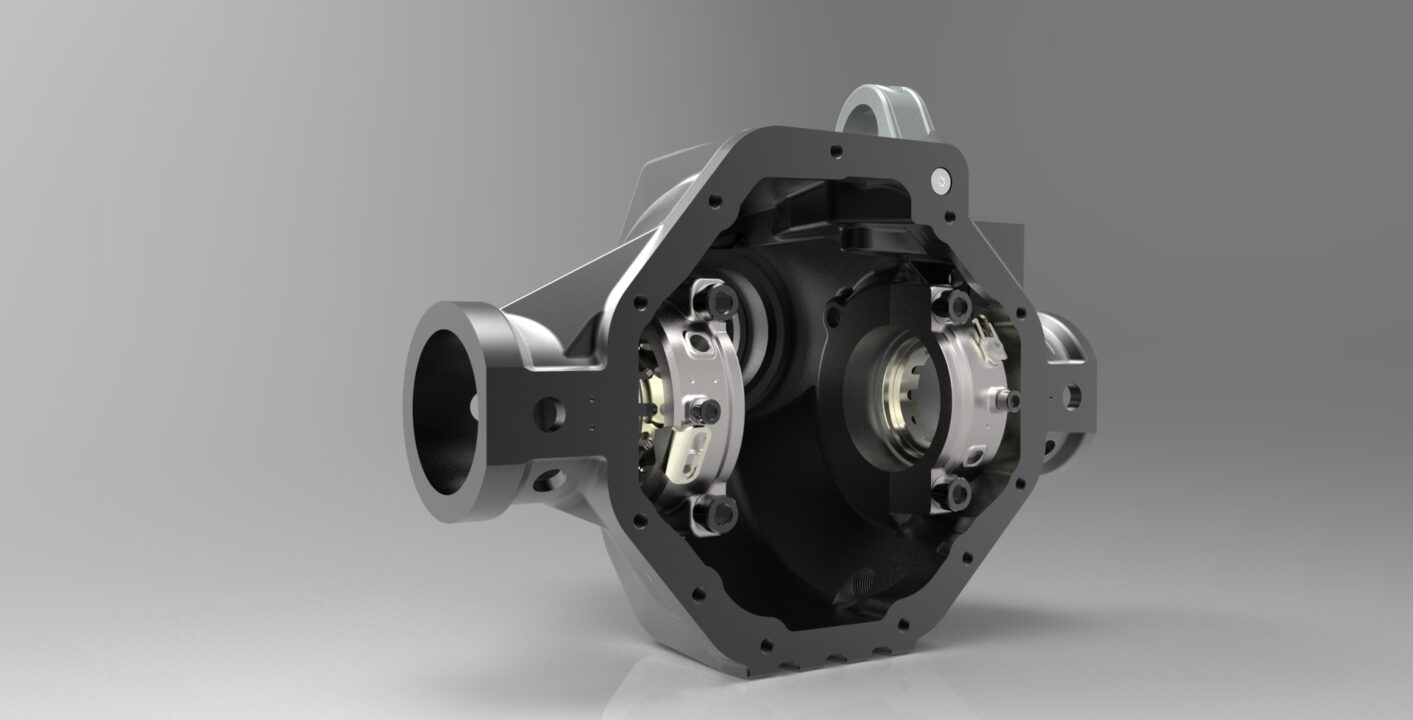

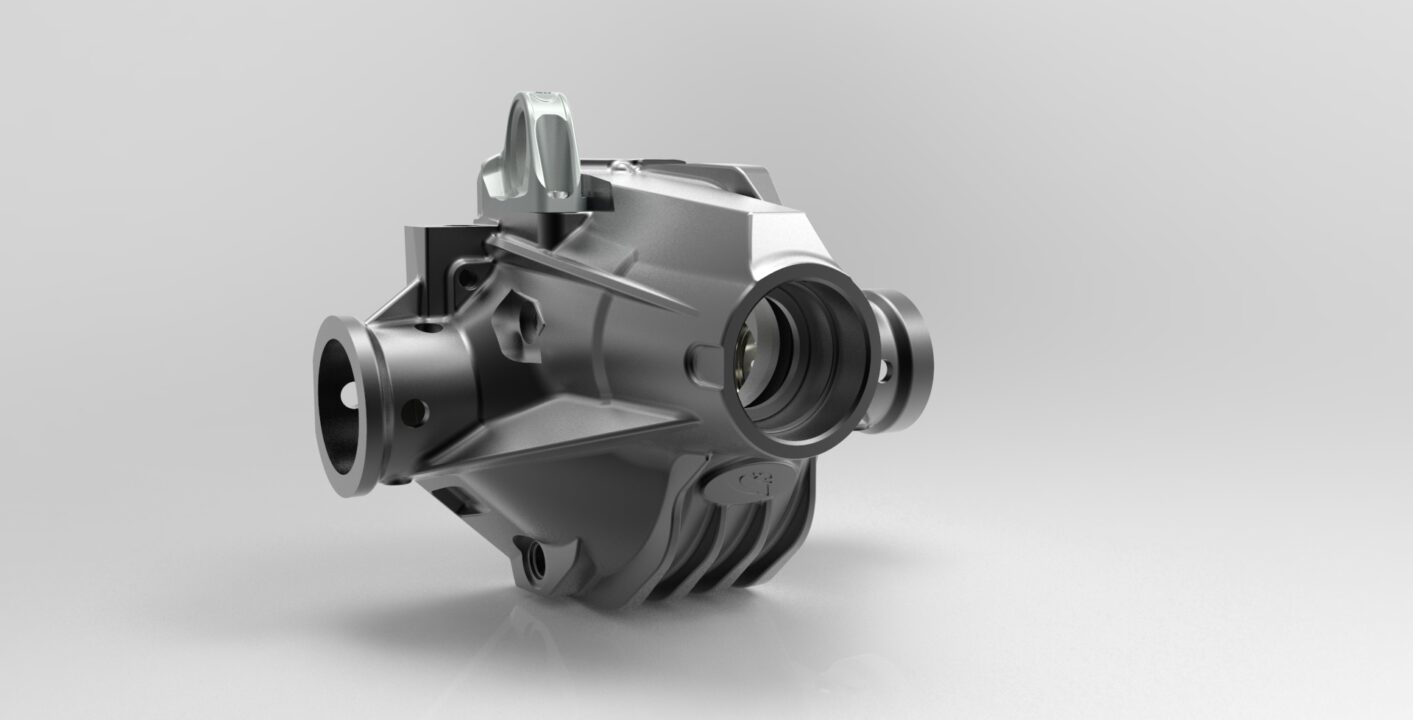

G2 Axle had a new Dana 44 Axle housing design but didn’t have enough resources to design and model the center section casting. Since we have a lot of experience designing complex cast and forged parts, this project was a good fit for us. So they had a laundry list of good ideas and we went to town. We took their list and added a couple of our own ideas to it. Like adding a unique adjuster spanner nut system that eliminated the need to use shims during assembly.

For this project, the devil is in the details! We used our expertise in ASME-Y-14.5 Geometric tolerancing to come up with a tolerancing scheme that adds a high level of consistency when manufacturing these housings. In the end we were very proud of the end product and it was a huge amount of teamwork to get this done!

More information on G2 Axle and their products can be found at www.g2axle.com